Why Does a Hybrid car battery require reconditioning?

The driving cycle of a hybrid vehicle subjects the battery pack to repeated shallow depths of discharge of less than 10% of the battery capacity. The unused capacity undergoes a correctable degradation process that reduces battery capacity. This failure process (i.e., module-to-module variation of amp-hour (Ah) capacity) is referred to as an “out of balance” pack. The modules have a memory of the small capacity demanded, thus resulting in the term “memory effect”

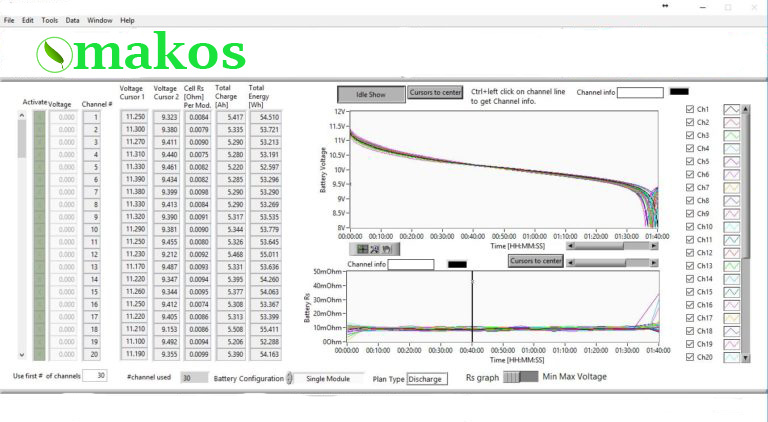

How do Makos achieve battery power regeneration?

Reconditioning recovers lost capacity. When reconditioned modules are sorted and positioned for optimum performance, the battery pack is balanced. The steps are:

1 Extract the hybrid battery pack from the vehicle

2 Remove the high voltage cable

3 Connect modules to our analysis and reconditioning machine (see photo above)

The output report:

a identifies high resistance modules .

b enables sorting and selecting of modules for pack assembly based on amp-hour or watt-hour capacity.

c pairs up modules into blocks based on module rest voltage.

d archives all data for your warranty management program.

How long does it take to recondition a hybrid battery pack?

High quality cell balancing requires a minimum of 20 hours on our reconditioning machine. NiMH modules have system parameters specific to the form factor (e.g., prismatic versus cylindrical) and number of cells in series (e.g., Ford Escape: 5; Prius prismatic: 6; etc.). These parameters govern the choice of recipe parameters.

The business model is:

1. Establish an inventory of reconditioned modules archived with watt-hour capacity and nominal module voltage data.

2. Replace customer hybrid batteries.

3. Recovery the battery core from the customer.

23 Comment(s)

I'm interested

1

1

I'm interested

1

Wow! Thanks so much for this post. This information has been very helpful. Thanks for sharing this post.

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

Leave a Comment